Our basis: 25 years of dry vacuum pump technology

VFD

(variable frequency drive)

Water lubricated bearings

Displacement machine

9 000 m³/h machine

weighs less than 180 kg

Highly efficient due to wet steam compression

Ethanol suitable

for sub-zero

for sub-zero

Wide operating range

up to 100°C

up to 100°C

Comparison of different Compressor Principles

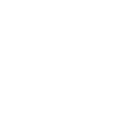

Impeller of a "Turbo" compressor

- dry running

- very high rpm

- huge transport volume

- low pressure ratio

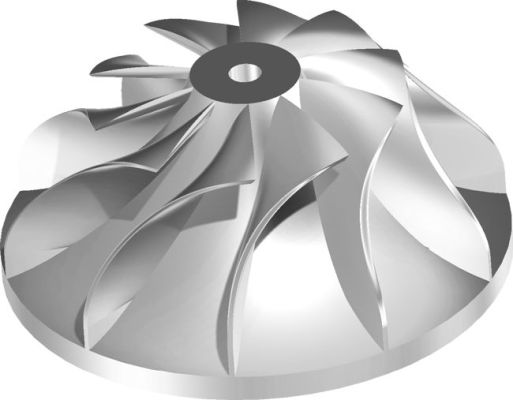

Rotors of a "Screw" compressor

- oil lubricated

- low rpm

- small transport volume

- high pressure ratio

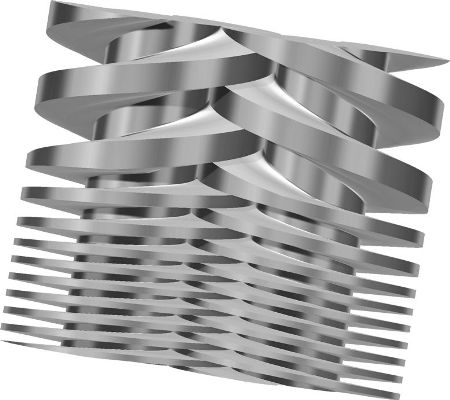

"Spindle" rotors as with a SIHIdry vacuum pump

- dry running

- multi stage

- high rpm

- medium transport volume

- huge pressure ratio

- medium volume ratio

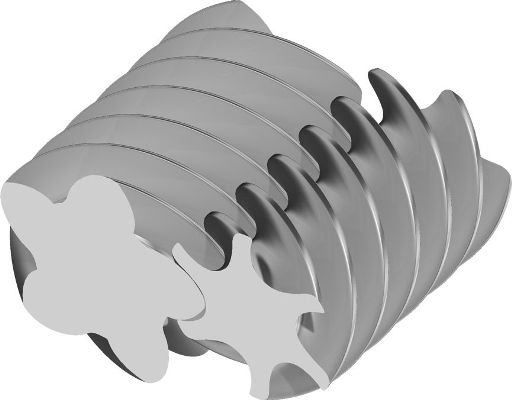

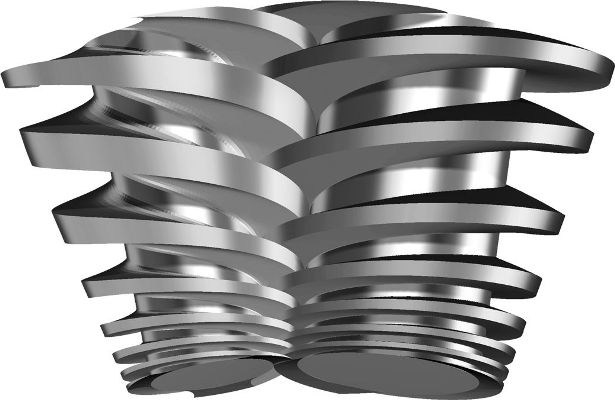

iCooler rotors (like a "Spindle")

- dry running

- multi stage

- high rpm

- high transport volume

- high pressure ratio

- high volume ratio

Results

Due to the huge gas volume of water, only a compressor with a high transport volume is useful. This eliminates the screw compressor. In addition, oil and steam should not mix.

This leaves the turbo and the spindle compressors.

For Water, the pressure ratio quickly exceeds values of 6. For example, the pressure ratio between the corresponding pressures of 2°C and 30°C is already 6.

This is only achievable with a two stage turbo compressor.

For heat pumps temperatures like 60°C are needed for hot water and starting at 2°C the pressure ratio is near 28.

Characteristics of the iCooler

The iCooler is an advanced R718 optimized spindle. It is capable of pressure ratios well above 20. A standard vacuum pump reaches values over 1 000.

To achieve high efficiencies the iCooler spindle rotors reduce the enclosed volume over several turns of the rotor to get as close as possible to an isentropic process.

For that reason the iCooler has a high internal volume ratio that can be reduced via pre-outlets to get a wide and efficient operating range.

Common Technology for R718 is a Turbo Compressor

The turbo is paving the way for the breakthrough of R718.

Solutions with a turbo are available for applications like IT, industrial process and building cooling.

These applications have in common the low temperature difference they require.

- Chilled water output preferably above 16°C

- Cooling water input preferably below 45°C

The next step: A new compressor to achieve higher temperature differences.

A higher temperature difference is equal to higher pressure ratios. This is needed to open up markets like heat pumps and several segments in the HVACR sector.

To attain this a displacement compressors is the optimal choice.

But compared to classical displacement (screw) compressors the transport volume has to be increased significantly.

High Transport Volume and Pressure Ratio with the iCooler

The way to a high transport volume screw.

A common screw is oil lubricated and this results in a low rotational speed.

Otherwise the hydraulic losses would increase noticeably.

Otherwise the hydraulic losses would increase noticeably.

This is not the case for dry running screw or spindle compressors. In fact they need the higher rotational speed to reduce back flow. This also increases the volume flow.

A spindle compressor has also a significantly higher transport volume at suction pressures below atmospheric pressure.

Due to its inclined axis, the iCooler has a further increased transport volume in relation to its size. This also results in a high volume ratio to meet the the volume ratio of water.

Higher COP thanks to Injection and R718

Water and Water + Ethanol have due to thier properties higher COP values especially at higher temperature differences. These values are further increased when compressing wet steam (injection).

These facts make the iCooler in addition to HVACR applications a perfect solution for heat pumps, even for industrial high temperature heat pumps.

The iCooler Model Series

The first available size of the iCooler will be 9 000 m³/h.

With this size, the cooling capacity varies between 30 kW and 95 kW depending on the evaporation temperature.

A high rotational speed results in a relatively compact and light weight compressor. The 9 000 m³/h version weights less than 180 kg.